OMNR Pump Toolkit

OMNR Pump Toolkit

Carleton University students in the School of Industrial Design had the opportunity to design or redesign equipment for wilderness firefighters in collaboration with the Aviation, Forest Fire and Emergency Services (AFFES) sector of the Ontario Ministry of Natural Resources and Forestry (OMNRF).

The design opportunities pertaining to the OMNRF’s pump toolkit were discovered on a field research trip to the Thunder Bay base. The toolkit appeared to lack any visible organization. Tools are unpacked onto the ground and get left behind and lost in the rough terrain. The heavy steel tools were packed in a standard 10lbs steel toolbox. I needed two hands to transport the box without discomfort as it was quite heavy (30lbs) and awkward to carry. I decided to redesign this product to reduce the weight, improve the method of carrying, organization, and stackability.

Existing pump toolkit

Design Opportunity

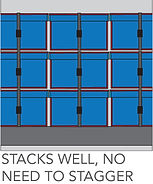

Existing toolkit is difficult to stack due to the handle on the top of the box.

This 30lbs kit is carried in one hand to the body of water nearest to the fire.

The tools are pulled out or dumped and left on the ground and often misplaced.

Contents of Pump Toolkit

Project Sketches

Use Cycle For New Design

Materials

91ju5IMU6cL._SL1500_.jpg |  bluecfvinyl.jpg |  121718_1.jpg |

|---|---|---|

31-Oy-S4X9L._SY300_.jpg |

Body structure: ABS

• High impact strength and stiffness

• Good chemical resistance

Corners, edges, and pockets: Cordura

• Wear and tear resistant

• Fire retardant properties

• Lightweight

• Durable, and tear and abrasion resistant

Main body shell: Vinyl.

• Easy to clean

• -40⁰ cold crack

• Fire retardant

• Anti-rot / anti-fungal

• Formulated UV protected

Pockets: Clear Vinyl

• Fire retardant

• Anti-rot / anti-fungal

• Formulated UV protected

Testing

Analyzing the optimal space needed so that there are no voids within the toolkit.

Determining the ideal placement of tools for organization purposes

Testing different ways of attaching the corners and creating hinges to ensure stability and strength of the structure

Testing the initial concept with a low fidelity model

Definitive Design

Most of the testing was performed on this model. The structure was sufficient to hold and secure heavy steel tools. This model reduced the weight by 4.6lbs in comparison to the original steel toolbox. Having a shoulder strap made it more comfortable to carry the weight as opposed to a handheld handle like on the original.

This first iteration of the concept folded out completely and had two pockets attached to the moving parts. This was altered to have less moving parts and so that it was manufactured in a more efficient way for maintenance.

Final Design

This final model is made of blue vinyl as blue is the most visible colour in the forest. The red accents are to create contrast to increase visibility. This model opens from the top to reveal pouches with tools organized by order of use.

The tools are organized by order of use within the toolkit and are stored in removeable pouches. The shoulder strap is detachable and can attach to the pouches for transportation. The pouch attached to the lid with snaps contains the tools that will be needed the most often. The pouches have water drain holes. All of the ABS panels are removable from the vinyl shell for ease of maintenance. They are kept in place with hook and loop. The shoulder strap has a rubberized grip to ensure that the toolkit does not slip off the user's shoulder during transportation.

Special thanks to

Chris Plater

Logistics Supervisor, OMNRF

Peter Brebner

Owner of Brebner Manufacturing & Repairs Inc.

Chantal Trudel

Contract Instructor, School of Industrial Design